Plastics recycling

Mechanical plastics recycling is a prime example of the circular economy. In general, a distinction can be made between post-industrial recycling and post-consumer recycling. There is no uniform definition of “post-consumer” in the various plastics processing industries. In general, plastics (waste) that have reached the end of their useful life, i.e. have been used by the consumer, can be categorized as “post-consumer”. Examples of this include the recycling of used refrigerators as well as the processing of plastic from the household waste collection, the so-called “yellow bin”.

We at HP-T Höglmeier-Polymer Tech, on the other hand, deal exclusively with the post-industrial recycling of plastics and are leaders in this field thanks to our decades of experience. As part of post-industrial recycling, plastic residues generated by various plastics processors, such as injection molding, extrusion or thermoforming companies, during their respective processes, is collected by type. If the respective application allows, these residues can be reprocessed as regranulate and fed back into the production process and thus reused. If this is not possible, the raw material cycle can be closed by another application in which the regranulate is used.

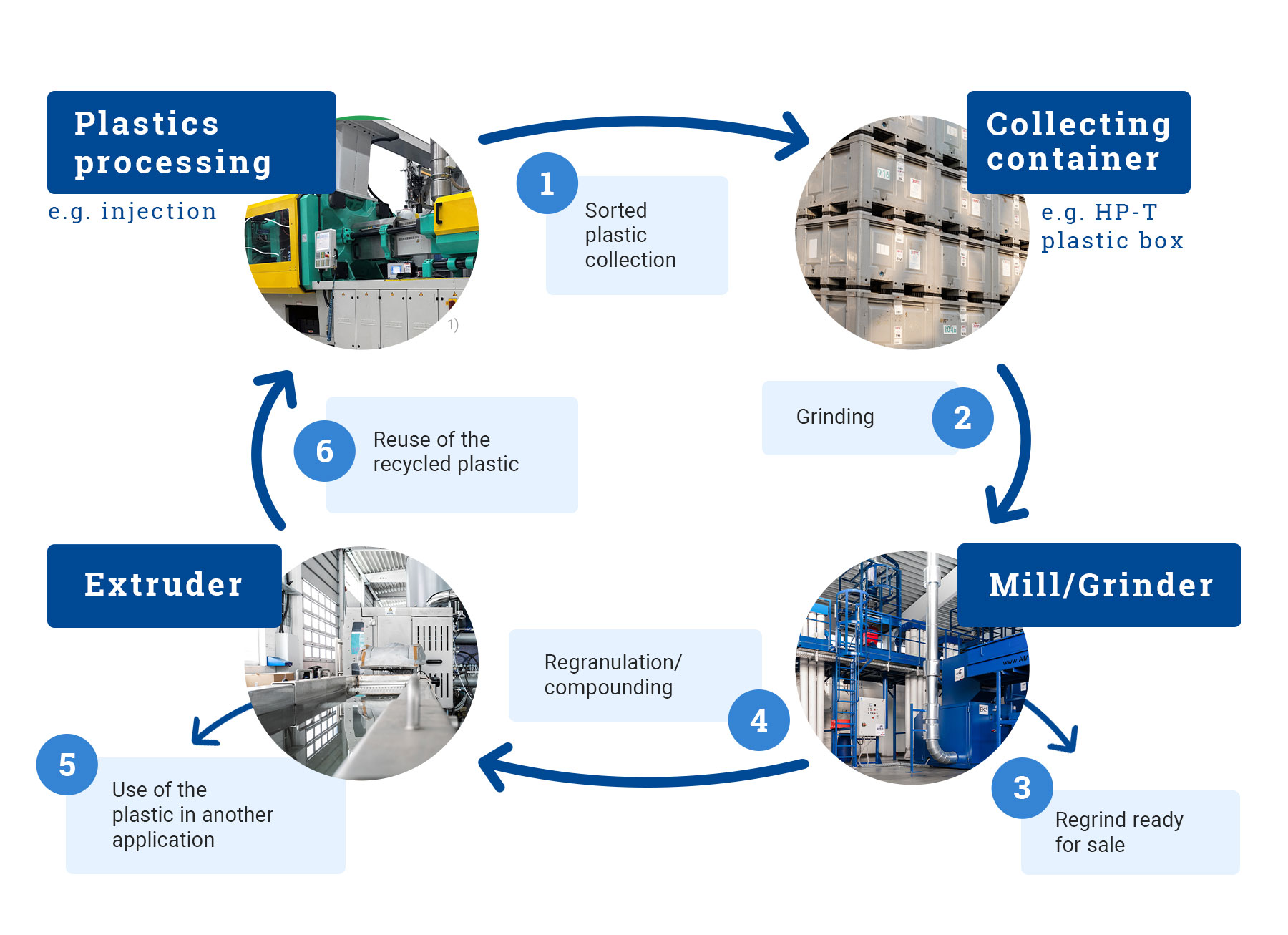

This is what the “ideal” closed cycle, that our team works towards every day, can look like. In this sense: responsible use of valuable resources!

The "ideal" circular economy

Our aim is to close these cycles, a “win3” for processors, the environment and for us as your strong partner!

1) Source: RF Plast

Plastic residues, e.g. sprues or faulty parts, are collected by plastics processing companies by type.

The plastic residues are shredded with the help of large granulators.

Regrind is sold on the open market. The cycle is closed by one of HP-T’s customers.

By further processing the regrind on a so-called extrusion system, regranulate can be produced. Alternatively, additives, masterbatches or glass fibers can be added, resulting in a new compound. This step is carried out according to customer requirements.

The regranulate/compound is fed into another application at one of HP-T’s customers. The recycled plastic is used again, creating a new cycle.

Ideally, the regranulate/compound is returned to the point of origin and reused there in the original application. This closes the “ideal circular economy”.